Is desalinated water safe to drink?

A Guide to Water Security

AI-powered software for reverse osmosis membranes to maximize performance, reduce energy consumption and extend membrane lifespan.

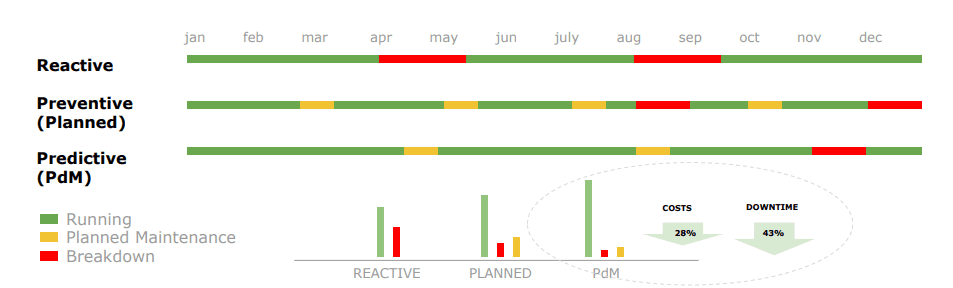

Desalination plants are still managed the traditional way: manually. This reactive approach leads to inefficiencies that silently erode your margins.

High-pressure pumps running at suboptimal settings waste massive amounts of electricity, your largest operational expense.

Over-dosing antiscalants chemicals to be "safe" is costly and environmentally damaging.

Early or late cleanings damage membranes, causing expensive replacements and high OpEx.

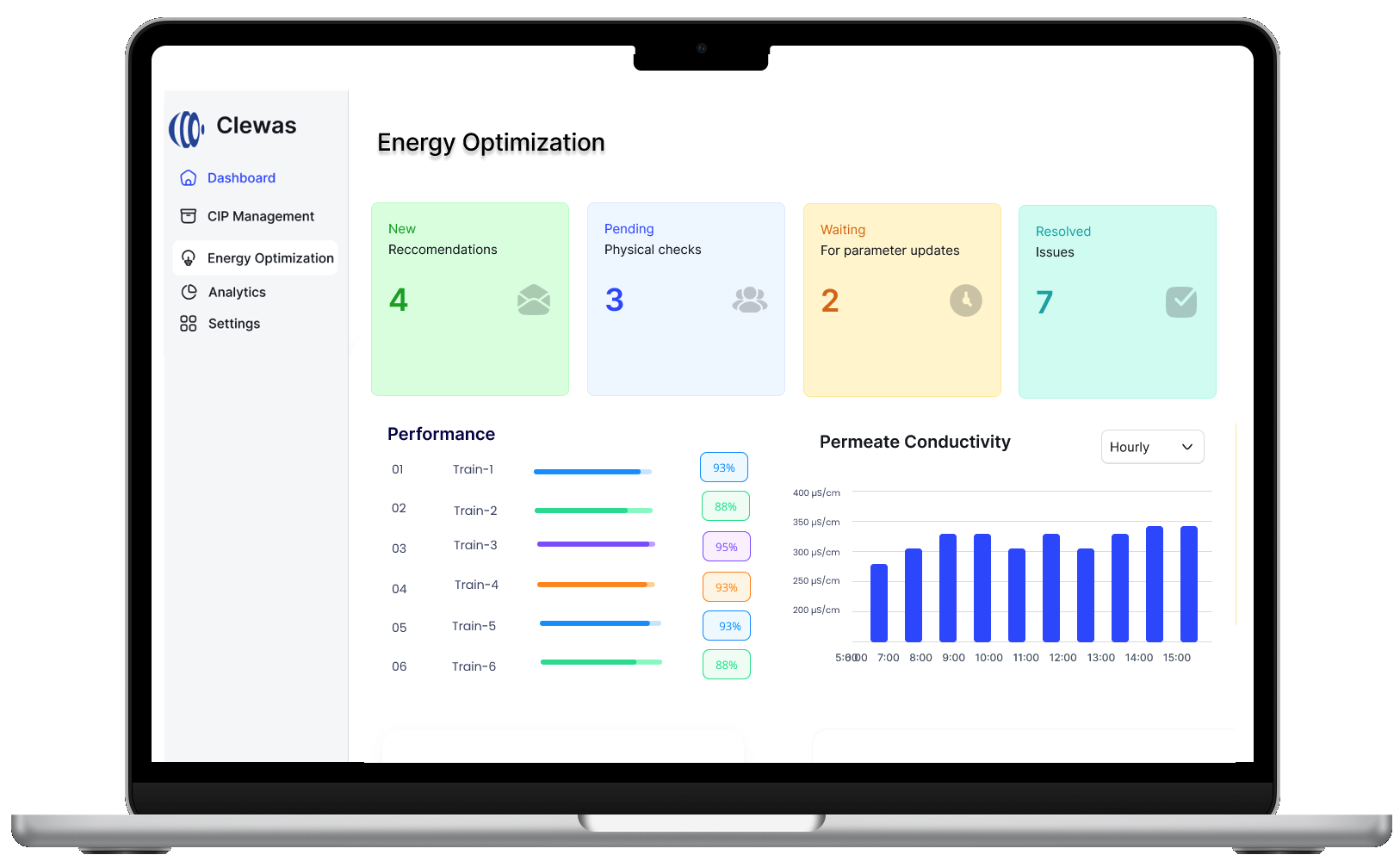

AI-Powered RO Optimization

AI-Powered RO Optimization

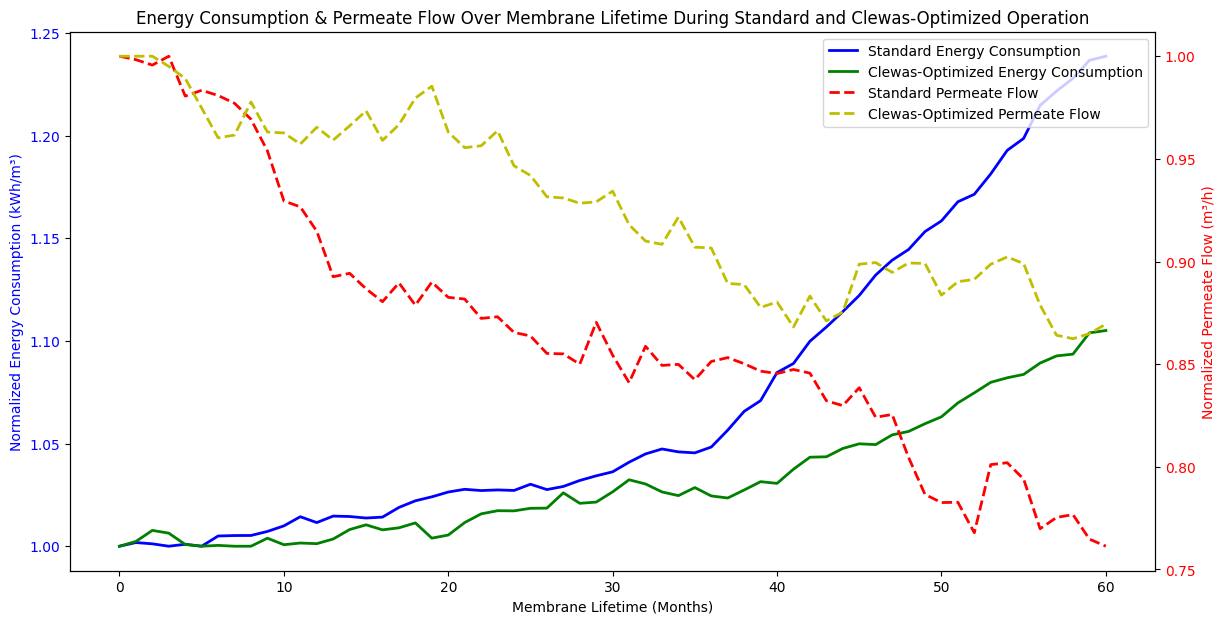

Our AI analyzes your conditions in real-time and recommends optimal pump pressure, flow rates, and recovery ratios; reducing energy consumption without sacrificing output.

Our predictive maintenance system tells you exactly when to clean weeks earlier, so you can plan accordingly and extend membrane lifespan by years

Get precise, data-driven dosing recommendations that reduce chemical costs while protecting your membranes from scaling and fouling.

Real-time monitoring and early warning alerts help you catch problems before they cause downtime, keeping your plant running smoothly.

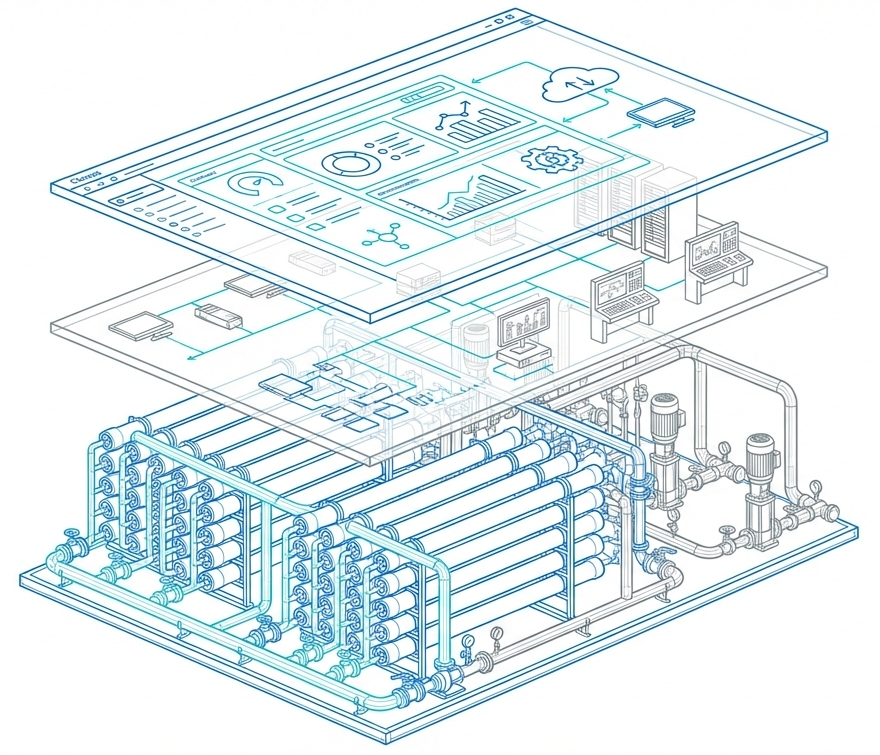

ROMax continuously monitors your system and delivers real-time recommendations that reduce energy costs, optimize chemical usage, and extend membrane lifetime.

Real-time system inputs

Historical Data

Past performance metrics

Design Data

System specifications

Operator Logs

Manual adjustments

Lab Test Results

Water quality analysis

PLC/SCADA Data

Live sensor readings

Actionable recommendations

Apply CIP in 24 days

Cleaning recommended

Adjust Parameters

Optimize production

Particulate Fouling detected

Check prefiltration equipment

See the difference between manual operation and AI-powered optimization

Operators stay in a safe zone and can't calculate precise setpoints

Can't predict what will happen before adjusting settings

It's not possible to predict operation parameters for the highest efficiency.

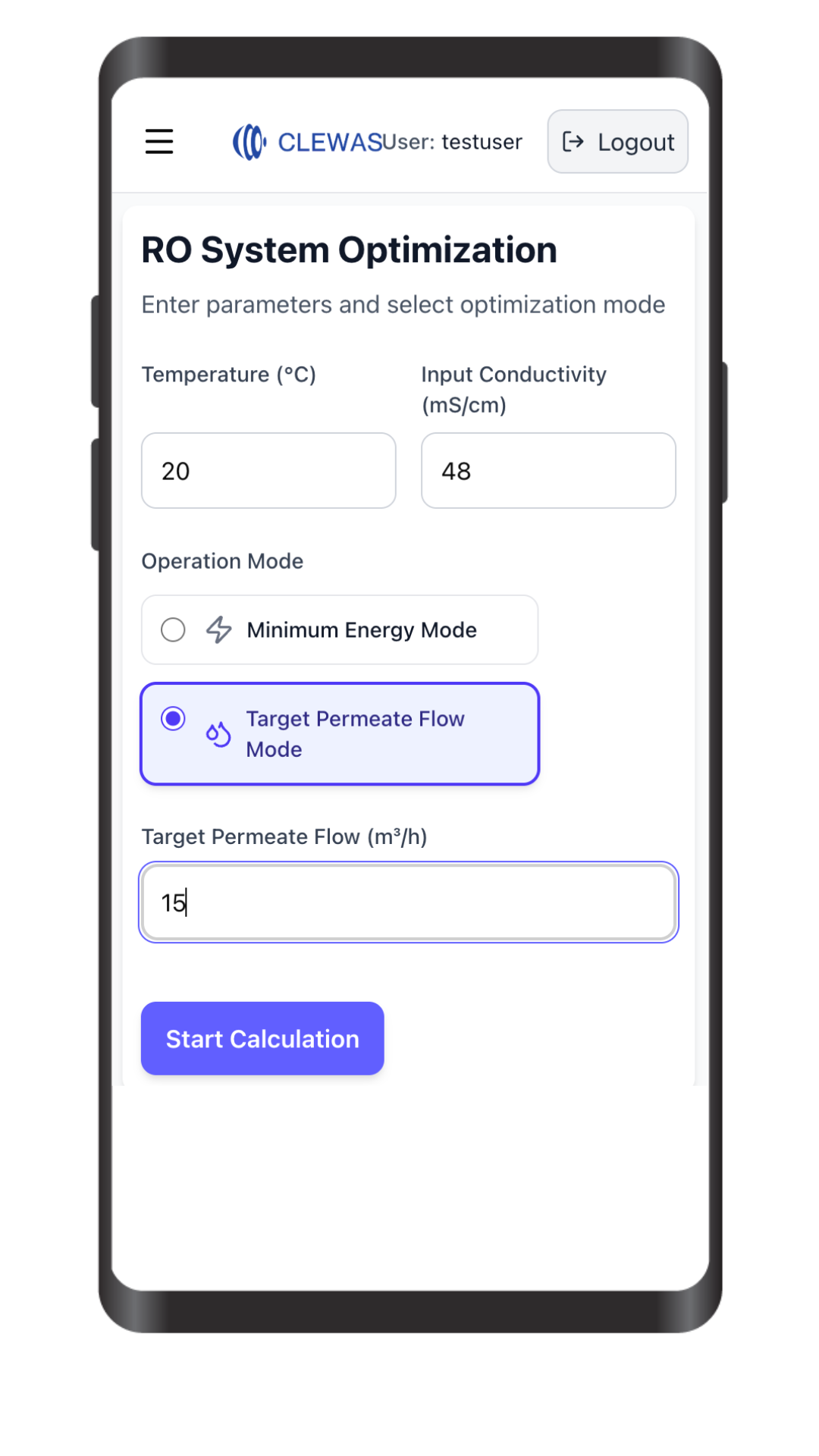

Product tank is mostly full, system can work with most economical setpoints with lower production flowrate

Operator chooses target flowrate and system calculates the best operation conditions for desired output

Every recommendation shows predicted results before you adjust anything

We analyze your plant's historical data to identify optimization opportunities and calculate your potential savings.

We implement monitoring and provide real-time optimization recommendations over a trial period. You see the results before committing.

Continuous optimization with 24/7 monitoring, predictive alerts, and ongoing recommendations that keep your plant running at peak efficiency.

Get a free analysis of your historical data and see exactly how much you could save.

Questions? Email us at info@clewas.com

A Guide to Water Security

Understanding the Challenges and Solutions

The Answer Might Surprise You

A Deep Dive into Mediterranean Disposal